Electric car battery technology

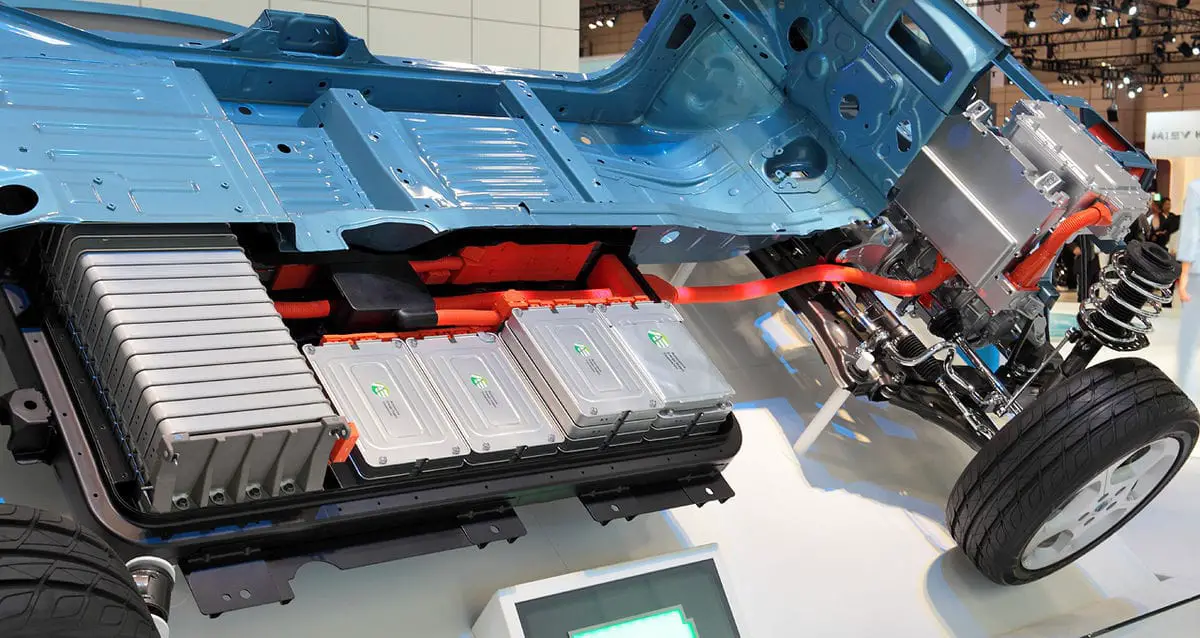

Battery electric vehicles (BEV) have an internal source of energy, an electric motor powered by electric batteries located in the vehicle. The powertrain gives BEV׳s the possibility to operate with zero emissions in the place of use.

Battery electric vehicles (BEV) have an internal source of energy, an electric motor powered by electric batteries located in the vehicle. The powertrain gives BEV׳s the possibility to operate with zero emissions in the place of use. Many of the manufactured solutions adopted to build BEVs also make use of an energy recovery technology that allows the electric motor to be used both as a propulsion source and as a generator when braking or when the vehicle moves freely under the action of gravity. This has an important effect in increasing the overall energy efficiency of the electric vehicle

EV batteries undergo cycles of discharge that occur when driving and charge when the car's plugged in. Repeating this process over time affects the amount of charge the battery can hold. This decreases the range and time needed between each journey to charge. Most manufacturers have a five to eight-year warranty on their battery. However, the current prediction is that an electric car battery will last from 10 – 20 years before they need to be replaced.

Compared to liquid fuels, most current battery technologies have much lower specific energy, and this often impacts the maximum all-electric range of the vehicles. The most common battery type in modern electric vehicles are lithium-ion and lithium polymer, because of their high energy density compared to their weight.

How a battery and the car's electric motor work together is surprisingly simple , the battery connects to one or more electric motors, which drive the wheels. When you press the accelerator the car instantly feeds power to the motor, which gradually consumes the energy stored in the batteries.

Electric motors also work as generators, so when you take your foot off the throttle the car begins to slow down by converting its forward motion back into electricity, this happens more strongly if you hit the brakes. This regenerative braking recovers energy that would otherwise be lost, storing it in the battery again and so improving the car's range.

EV battery Lithium-ion

Lithium iron phosphate cathodes that are free from cobalt. That’s particularly important because cobalt is a mined resource that’s costly and often linked to unethical mining practices.

Iron and phosphorous are readily available resources, and procurement of these elements could drastically reduce the environmental impact of mining for cobalt to use in batteries. Lithium iron phosphate batteries have longer lifecycles and higher discharge and recharge rates. The trade-off is that iron phosphate has a lower energy density so battery packs could increase in size.

This battery is a type of rechargeable battery used in electric vehicles and a number of portable electronics. They have a higher energy density than typical lead-acid or nickel-cadmium rechargeable batteries. This means that battery manufacturers can save space, reducing the overall size of the battery pack.

Lithium is also the lightest of all metals. However, lithium-ion (Li-ion) batteries contain no lithium metal, they contain ions. For those wondering what an ion is, an ion is a an atom or molecule with an electric charge caused by the loss or gain of one or more electrons.

Lithium-ion batteries are also safer than many alternatives and battery manufacturers have to ensure that safety measures are in place to protect consumers in the unlikely event of a battery failure. For instance, manufacturers equip electric vehicles with charging safeguards to protect the batteries during repeated rapid charging sessions in a short period of time.

Glass Battery

The design adds sodium or lithium to glass to form an electrode in the battery. Making it appropriate for mobility applications are the facts that it’s more stable than other sources, can handle temperature extremes better, and is relatively low cost to produce.

Glass battery technology can be able to store three times the energy of a traditional lithium-ion battery of a similar size and can withstand many more charge and discharge cycles than typical EV batteries. The potential includes reducing battery sizes and weights with the same range and performance, or maintaining the size and weight in a vehicle and extending the range by up to three times. The 1,000-mile EV barrier could be broken eventually.

Lithium Sulphur Batteries

Like lithium iron phosphate, lithium-Sulphur could become a replacement for batteries that contain heavy metals. Researchers at Monash University have developed a lithium-Sulphur battery design, tested on a cell phone, that held charge for five days. As a common element, Sulphur would greatly reduce the mining costs that impede EV battery development and adoption.

Monash researchers theorize that lithium-Sulphur batteries can store more energy than lithium-ion by as much as six times. Until now, they have been unstable as the energy causes the battery to break apart. A commercial product is expected in two to four years.

Source: eDF, ScienceDirect, Mes insight