Electric car battery Frequently Asked Questions.

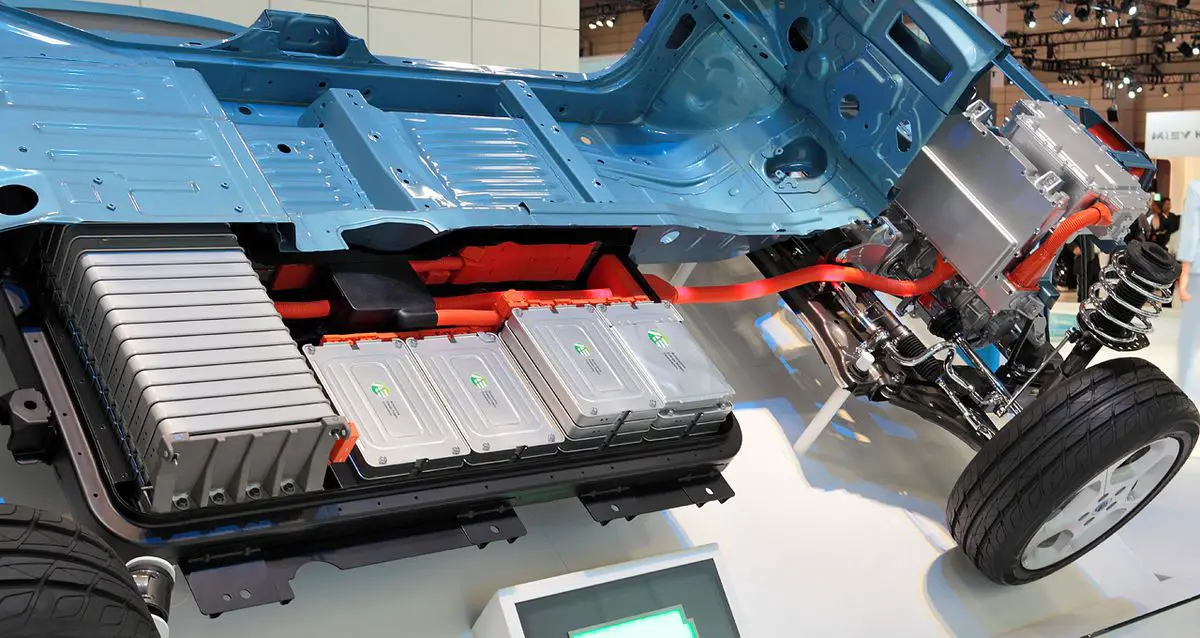

Electric car batteries are the heart of EV, they determine how far you can go and how long you will take to recharge. There have been several concerns on the batteries such as where you can find a replacement for the battery

Electric car batteries are the heart of EVs, and they determine how far you can go and how long you will take to recharge. There have been several concerns about the batteries, such as finding a replacement for the shower and warranty. We have to sort the frequently asked questions, and we will give you the answers for them.

After five years, will I need to replace my battery?

It is an excellent question that we can typically answer straight away; the answer is no, or it isn't definite. Your battery's current prediction will last at least ten years and maybe up to 20 years before having to replace it. The performance of the storm has dramatically shocked the public on the many produced electric cars.

In case I need to replace my battery, what should I do?

As said above, the battery can take 10-20 years before they need to replace it. However, if by any chance you need to replace a storm, it would be possible. There has never been any case of severe battery degradation ever experienced. We tend to believe that a 15-year-old Nissan Leaf has an advantage because its battery is bigger, better, and cheaper. After all, Leaf was the first electric car in the market, and as it's said, old is gold. The battery can go up to 200 000 miles before the need to replace it.

If there is a manufacturing fault?

If the vehicle faults within the warranty period, it is the manufacturer's responsibility to replace the battery. And in case the owner decides that they would like to replace the battery outside of the warranty, they can often pay to do so. For example, there are no battery options; therefore, should you experience any fault, you will have to return the car to the manufactures to replace it.

However, it would help if you considered these batteries hardly fail; according to 2015 data released on 35,000 Leaf's sold, only 0.01% equivalent to three cars were not effective.

Incase your EV is suffering from battery degradation outside the warrant, then the only option left is to go for reconditioning service. It would involve analyzing your battery and replacing several damaged cells. It can cost around £1500.

What happens to leased battery?

A battery leased EV such as most Renaults or the Nissan Leaf Flex is an arrangement by which you own the car but "rent" the batteries. It was a typical arrangement at the early stages of EV adoption as owners were concerned about battery performance. As time has gone on, the technology has more than proved itself.

Now, a battery lease is mostly there to make the purchase of an EV affordable. In most cases, the battery is the most expensive component in the vehicle, so by renting the shower, you can buy the car for a significantly reduced cost.

Some owners may still choose the leased battery option to maintain a warranty against the battery. As the leasing company owns the storm, they must strengthen the battery's capacity and fix it to fail or degrade. Battery leases typically also include extras such as roadside breakdown cover.

Should I buy a used car with a leased battery?

This all depends on how you want to approach an electric vehicle's finance and the car you are looking at. For example, the Renault Zoe can most commonly be found with a leased battery. This makes the Renault Zoes the cheapest used EVs on the market today.

Do I need to charge my EV battery every day altogether?

No. With ranges higher than 300km, in most cases, there is no need to fully charge the battery, except if one plans to make a long journey. With such a use pattern, the battery will keep a better state of health. Also, keeping the State of Charge (SoC) of the battery at an intermediate level has the long-term potential to allow owners to make revenues by offering services to the grid through Mobility Service Providers, Aggregators or similar service providers, for instance via smart charging (V1G) and Vehicle-to-grid (V2G).

What if charge runs out?

It is same as convenvectional vehicle. A tow company will come and rescue you from the side of the road. However, it just doesn't happen. When you own an EV, you typically get in your car every morning with a full battery and maximum range.

That means always you can drive the same distance. You don't get surprised when you look down at your predicated range. The perceived ease of filling up with petrol or diesel leads to a complacency that causes more problems than it saves.

How is the range affected by extreme ambient temperatures?

The real autonomy of electric vehicles is affected by temperature conditions, the battery's autonomy being lower when temperatures go down. Batteries are temperature sensitive, but modern electric cars have insulated showers that are heated in winter. The independence prescribed by OEMs is measured following new procedures. The current WLTP measures are better and more efficient than the previous actions, making the difference observed in ambient temperatures smaller than before and more accurate to reflect real driving conditions.

What is the impact of battery manufacturing and production on the environment?

Batteries are energy-intensive products. With the upstream emissions from mining, refining, and transportation of the materials, the carbon emissions from the production of batteries account for about 20% to 40% of the total lifecycle greenhouse gas (GHG) emissions of electric cars. 50-70% of a traditional battery's total carbon footprint is related to the energy consumption in the production process. The manufacturing step of the production process also accounts for a large share of the total carbon footprint. For instance, producing 1 kWh battery capacity requires about 60-80 kWh energy consumption.

Several improvements contribute to the decreasing environmental impact of battery manufacturing. These range from:

• The use of carbon-neutral electricity generated on-site as well as the decarbonization of the electricity grid across all EU countries;

• Efficiency gains in the manufacturing processes, among others thanks to economies of scale;

• Battery chemistry and density improvements that allow us to produce batteries with less raw material and reduce or eliminate the use of the most impactful materials such as cobalt;

• Recycling of battery materials through dedicated recycling facilities striving towards more efficient and environmentally optimal processes;

• Continued efforts to incorporate increasing rates of recycled materials in new batteries;

• Vertical integration and relocalization of the production process to reduce the impact of transportation.

Will we run out of certain raw materials needed for EV production?

A sustainable and competitive global raw materials supply chain is key for the accelerated production of EVs across Europe. Currently, the majority of raw materials (i.e., cobalt, lithium, nickel, manganese, and graphite) needed to power electric cars are found and mined outside of Europe, specifically in Asia, Africa, and South America.

Notably, most of the global supply of cobalt (64%) is found in the Democratic Republic of Congo. Furthermore, a large increase of metals will be needed for EV batteries to meet rising expected demand. Specifically, it has been found that we will need three times the amount of cobalt to meet the expected demand by 2025, surpassing actual 2018 global production and 3.5 times for lithium, representing 75% of the global production by 2025.

The EU is in the process of taking concrete action to address the potential risk of running out of key raw materials. Simultaneously, the EU has the ambition to develop its own domestic raw material industry as a lever for economic growth. In terms of legislation, the EU is developing an overarching Battery Strategy that will, amongst other things, regulate and incentivize how lithium-ion EV batteries are recycled in Europe. It will be one way for the EU to secure reliable and sustainable access to relevant secondary raw materials and ensure that these materials stay on the continent.

Won't EV batteries end up in landfills?

A major misconception about EV batteries is that they are not collected and recycled but rather end up in landfills with a negative impact on the environment. From a legislative point of view, the Batteries Directive already forbids landfilling and incineration, resulting in an implicit 100% collection target for automotive and industrial batteries.

EV batteries are also already regulated as part of the vehicle they are placed in. The obligation to collect end-of-life vehicles is already described at the End of Life Vehicles (ELV) Directive. The car owner's involvement in servicing electric powertrains currently is and is expected to stay minimal, and professional actors actively participate in the implementation of efficient take-back systems. However, the ELV Directive is expected to be revised to prevent illegal exports of vehicles outside of the EU and ensure that they are properly and effectively tracked and collected.

(Electric Vehicle Batteries Frequently Asked Questions (FAQ). www.motus-e.org/wp-content/uploads/2020/06/MOTUS-E_Electric-Vehicle-Batteries-Frequently-Asked-Questions-FAQ-Platform-for-Electromobility-2.pdf)

Source: Drive Green, Electro mobility